Index

ToggleFireproof materials are increasingly important, protecting people and assets from the risk of fire. Currently, the market has developed many types of materials capable of preventing the spread of fire, each with unique characteristics regarding durability, fire resistance rating, complexity of construction, and cost. So, what are fireproof materials, and which type is best suited for your project? Let’s find out in detail with Co-IDB to make the right choice.

What are Fireproof Materials?

Fireproof materials, or “fireproof material” in English, are materials capable of slowing down and preventing the spread of fire, helping to protect people and assets in case of a fire. These materials can withstand high temperatures for a long time, minimizing damage as much as possible if a fire occurs.

Although there are non-combustible materials with similar properties, their fire resistance level may not be as high. Currently, there is no material that is 100% absolutely fireproof; however, office buildings and factories still prioritize the use of fire-resistant insulation materials as an optimal safety solution.

>> Read more: Top 10 Eco-Friendly Materials for Green Workspaces

Fireproof Material Standards

Standards for Fireproof Partitions

Fireproof partitions in offices must undergo comprehensive testing according to the entire design system, not just based on one or a few individual panels. To meet fire resistance standards, fire-resistant gypsum board partitions must satisfy the following factors:

-

Insulation property: Ability to withstand surface temperatures up to 140°C and a maximum of 180°C at certain points.

-

Fire resistance limit: The duration of fire resistance (in minutes) during the experiment before the structure begins to degrade.

-

Integrity property: The ability to resist cracks and holes to prevent the transmission of hot gases.

-

Stability property: Durability to maintain the original structure when exposed to fire.

To meet the standard, gypsum partitions must use fire-resistant materials such as KHS FA board, **glass fiber wool**, which allows the partition to resist fire for approximately 30 to 150 minutes.

Standards for Fireproof Doors

Size Standards

The size of fireproof doors for offices is regulated with specific standards as follows:

-

Standard dimensions: Door width ranges from 800 – 1200mm and height from 1800 – 3000mm, suitable for clear passage, ensuring safety.

-

Steel thickness: Fireproof door leaves are made of steel with diverse thicknesses from 0.8 mm to 2.0 mm depending on the fire resistance requirement.

-

Door leaf thickness: Fireproof door leaves must have a minimum thickness of 40 – 50 mm to ensure structural durability and optimal fire prevention efficiency.

Fire Resistance Rating Standards

The fire resistance rating, also known as the fire resistance limit, of a fireproof door is determined based on the time the door can maintain its structural integrity and prevent the passage of fire, smoke, and gas. According to **TCVN 9383:2012** (Vietnam National Standard), fireproof doors must ensure a minimum fire resistance of 45 minutes and a maximum of up to 180 minutes.

Below are the standard fire resistance ratings for office doors:

-

EI60 Fire Door: Resists fire, prevents smoke, and withstands heat for a minimum of 60 minutes.

-

EI70 Fire Door: Resists fire, prevents smoke, and withstands heat for a minimum of 70 minutes.

-

EI90 Fire Door: Resists fire, prevents smoke, and withstands heat for a minimum of 90 minutes.

-

EI120 Fire Door: Resists fire, prevents smoke, and withstands heat for a minimum of 120 minutes.

Placement and Material Standards

According to TCVN 9383:2012, the requirements for fireproof doors in offices and high-rise buildings are as follows:

-

Windows, doors, and fire partitions in rooms must be made of fireproof material, ensuring a fire resistance of at least 45 minutes.

-

Windows, doors, and fire partitions in basements and on the roof must be made of non-combustible material, with a minimum fire resistance limit of 40 minutes.

-

Emergency staircase doors, technical room doors, and basement doors in high-rise buildings and apartments must be made of fireproof material, equipped with an automatic closing mechanism, and achieve a minimum fire resistance time of 45 minutes.

Some Other Standards

Additionally, when choosing fire doors for offices, customers should note the following requirements:

-

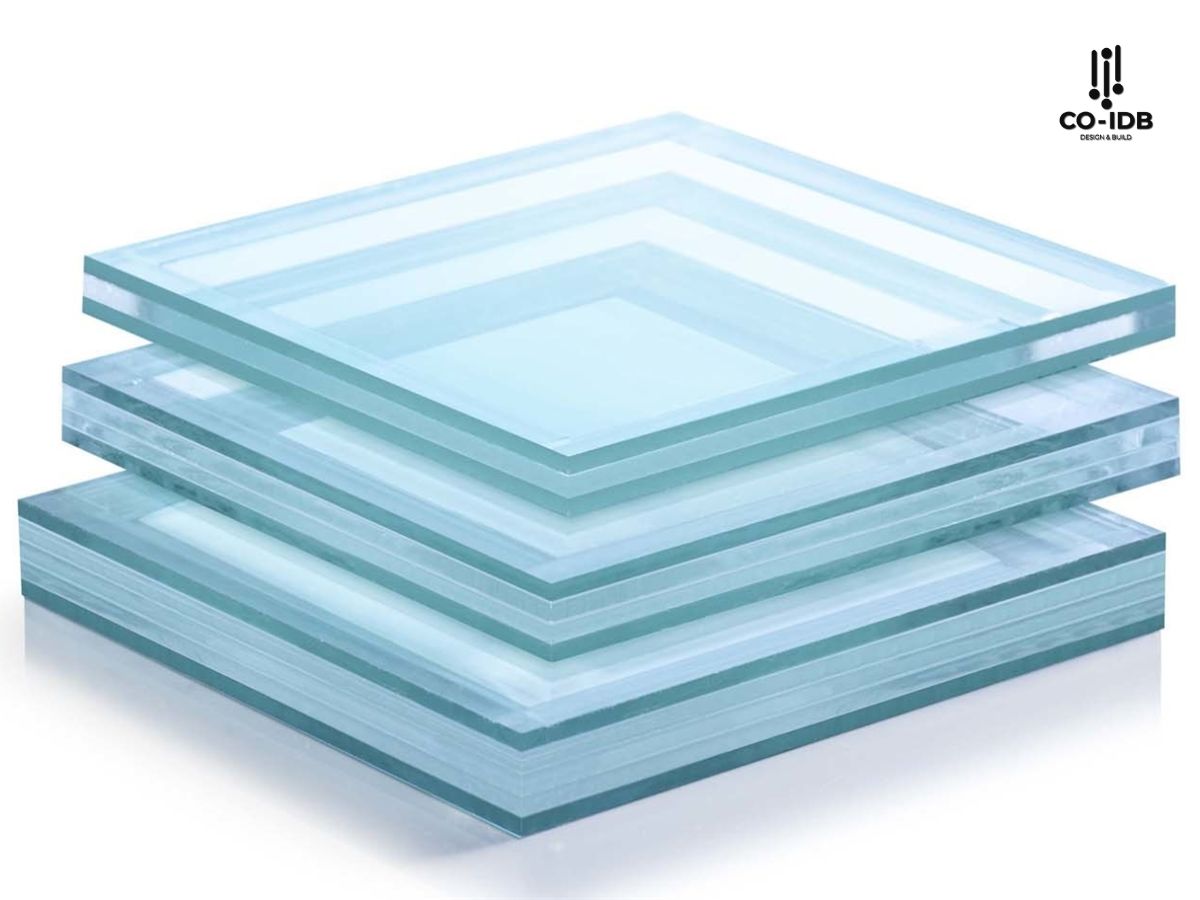

Fire-resistant glass: If the door has a glass panel, the glass must be fire-resistant, such as tempered glass with a steel mesh layer.

-

Fireproof door core: The door core needs to be made of fireproof material like magnesium oxide (MGO), honeycomb paper, or rockwool glass wool.

-

Rubber gasket: The door must have a surrounding rubber gasket system, creating a sealed structure to prevent smoke spread.

-

Fireproof accessories: Depending on the location, the door should have accessories such as a hydraulic door closer, panic bar, and lever handle lock.

Top 7 Popular Fireproof Materials in the Construction Industry Today

Fire-Resistant Reinforced Concrete

When mentioning fire spread prevention and fire/explosion containment materials, reinforced concrete cannot be ignored. With main components including a steel core, cement, sand, stone, and additives, concrete stands out for its effective heat resistance and fire prevention capabilities. These materials are all difficult to ignite, giving concrete the optimal ability to insulate heat and prevent the fire from spreading widely.

Currently, fireproof concrete is widely applied in almost all construction projects, from large-scale projects like factories and industrial parks to civil works such as residential houses and production workshops.

3.2. Fireproof Doors

When a fire occurs, the door is the exit route most people think of first. However, if the door is flammable and not heat-resistant, the situation becomes extremely dangerous.

To ensure safety for projects, from residential homes to office high-rises, engineers have developed specialized fireproof doors. Fireproof doors not only resist heat and fire for a long time but also effectively prevent smoke spread.

Currently, popular types of fireproof doors include fire-rated steel doors, fire-rated glass doors, etc. Fire-rated steel doors typically have a three-layer structure: two outer steel layers, a core of glass wool or insulated foam in the middle, and a sturdy steel frame. The rubber gasket system around the door helps prevent smoke effectively. These doors can withstand high temperatures for up to 120 minutes, meeting strict safety standards.

Fire-Resistant Gypsum Board

Gypsum board is manufactured from natural gypsum mineral; after extraction, this mineral is ground into powder and mixed with water to form a plaster slurry. After curing, the gypsum slurry sets and turns into construction gypsum.

Gypsum material possesses many outstanding advantages: light weight, good thermal insulation, effective fire resistance, impact resistance, and it is eco-friendly, posing no harm to human health.

In construction, gypsum is often used as a fireproof material for projects, including ceilings and partitions. Fire-resistant gypsum partitions are currently very popular and widely applied in many projects.

Some practical examples of using fire-resistant gypsum panels include: Vincom Center shopping mall, Bitexco Tower, and Ecopark residential complex, etc.

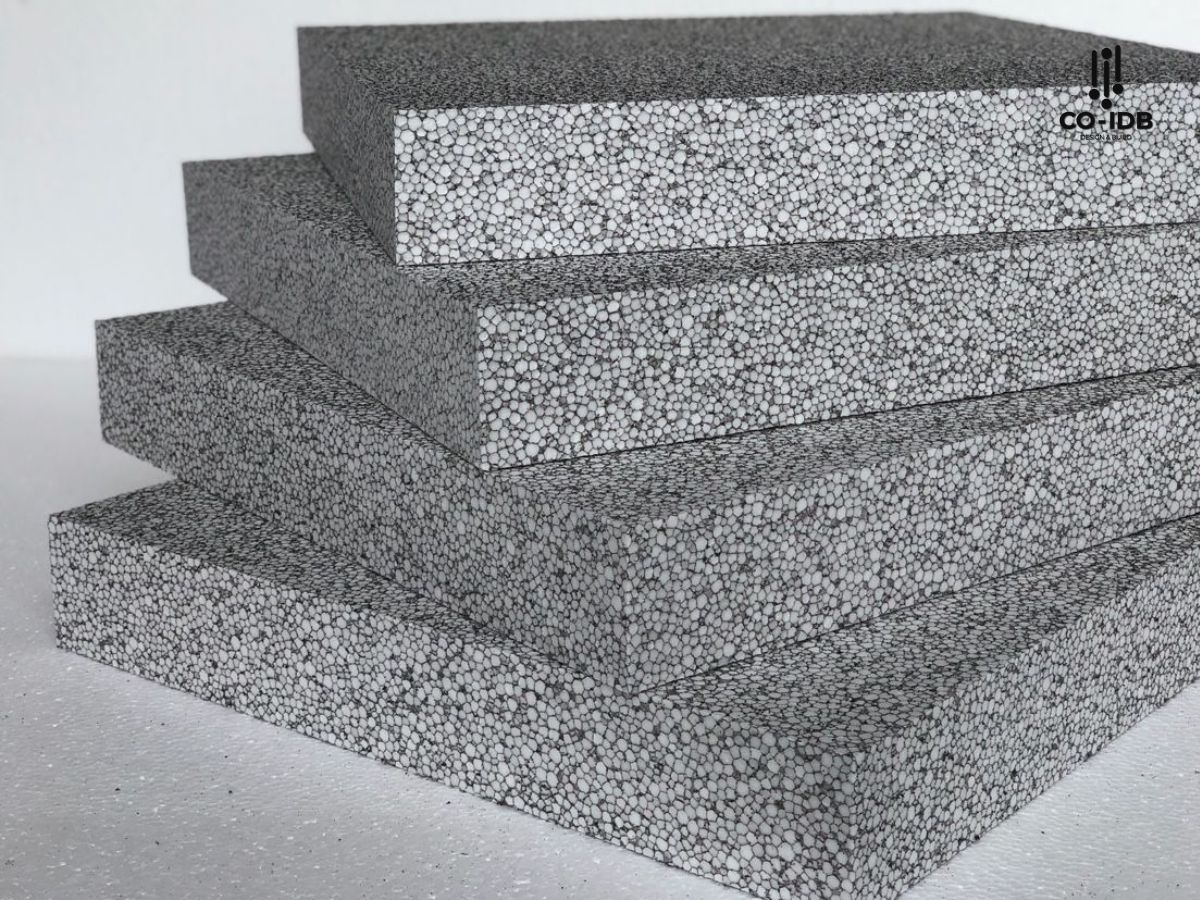

Fire-Resistant Foam Brick (Gạch mát)

Foam brick (Gạch mát) is structured with two thin layers of special cement on both sides, with a layer of Polyurethane plastic in the middle. This industrial plastic stands out for its high durability, excellent shock resistance, and superior elasticity.

Not only that, foam brick also has good thermal and sound insulation capabilities, so it is often used for items such as soundproofing floors, fireproof wall cladding, and fireproof ceilings. Thanks to these characteristics, foam brick is a popular choice for projects that require ensuring safety and efficiency.

Fire-Resistant Glass Wool

Glass wool, as its name suggests, is manufactured from synthetic glass fibers, mainly from rock, slag (a by-product of metallurgy), and clay.

With outstanding features such as thermal insulation, sound insulation, electrical insulation, low flammability, and good elasticity, glass wool is an ideal choice for many applications in construction. For instance, it is often used as the inner lining for various types of fire-rated steel doors.

Furthermore, in the field of industrial construction, glass wool is also used to manufacture various fire-resistant, thermal insulation, and sound insulation materials, serving factory buildings, manufacturing plants, industrial parks, and export processing zones. This helps ensure safety and efficiency for modern projects.

Fire-Resistant Glass

Fire-resistant glass is composed of two layers of glass, bonded together by one or more layers of fire-resistant film (thermal insulation film). Fire-resistant glass not only has the ability to stop fire but also helps prevent fire spread, extending the time and minimizing damage as much as possible in the event of a fire. Thanks to this outstanding feature, fire-resistant glass is increasingly favored in modern architectural design.

>> Read more: Compilation of Popular Interior Materials for Office Decoration Today

Engineered Fire-Resistant Wood

In contrast to natural wood, which is easily flammable, engineered wood stands out with its superior fire resistance. Fire-resistant wood is mainly divided into two types: wood-plastic composite (WPC) and melamine-faced chipboard (MFC).

Wood-plastic composite (WPC), also known as plastic wood, is composed of wood flour and plastic, providing excellent fire resistance and heat resistance. Meanwhile, melamine-faced chipboard (MFC) has a simpler structure, primarily made from conventional wood but coated with an additional layer of melamine which has fire-resistant properties.

With outstanding advantages in fire resistance and high aesthetic value, fire-resistant wood is widely applied in many projects, in the design of **wood furniture**, particularly for manufacturing fire-rated doors, contributing to increased safety for office spaces and residences.

Fireproof materials play a crucial role in protecting the safety of construction projects and office designs. The selection and use of these materials not only help minimize fire risks but also ensure aesthetics and comfort for the workspace. To receive more detailed consultation on fireproof materials, please contact Co-IDB today!

>>> Read more: